Top 7 Benefits of Staff Augmentation

31/07/2024

Top 7 Benefits of Working with a Staffing Agency

04/08/2024Europe is the most technologically advanced continent after North America. But it would surprise you that only 15% of the manufacturers have real-time visibility into the production line. What does this mean for the rest of the world? We can assume near-similar visibility or even poorer visibility. And we are right. Globally, the figure is at 16%.

Is 5G the Only Answer?

5G could be the answer to this problem and some others that are affecting manufacturing right now. Augmenting the workforce with advanced robotics and training teams to work with them is another option. The future may be a mix of both, and with insights driven by AI. When the trio come together, the future looks very interesting for manufacturing. In this article, we look at how 5G can play the lead role in manufacturing for the future.

What is Industry 4.0?

Simply put, Industry 4.0 will be the next phase for the industrial processes in the world. In other words, it is the fourth industrial revolution. The first one began in Europe in the 18th Century. Industry 4.0 will be the coming together of advanced AI, IIoT (Internet of Things), cloud computing and Augmented Reality, and even advanced biology to engineer the next wave.

According to IBM, the definition of Industry 4.0 is “the realization of the digital transformation of the field, delivering real-time decision-making, enhanced productivity, flexibility and agility to revolutionize the way companies manufacture, improve and distribute their products.” This definition helps us understand Industrial 4.0 from the POV of the benefits it provides.

How Is 5G Different from 4G?

Where 4G introduced packet switching and message switching (two ways of transmitting data over the network) over 3G and increased the channel width, 5G has taken the time synchronization feature in 4G to bring in more stringent demands on accuracy. Why is such accuracy required in 5G? to support several client devices and to serve as many as a million devices in a square kilometer.

In other words, 5G is already ready for the technologies that will fill the supercities of the future. Can you imagine a bus with just 30 employees but with a thousand IoT devices sensing and communicating to a control center situated at the workplace? A 5G network can make this possible. 5G is also a super-enabler rather than just a technology, as it will enable other technologies like AI and AR and make them work well over a very wide network.

Why is 5G Crucial to Manufacturing?

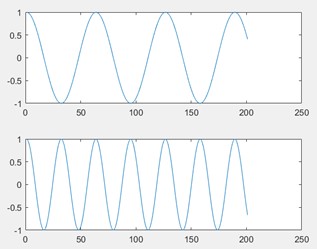

This brings us back to what we spoke about in the beginning. Real-time visibility over the production line. And the concept that makes 5G achieve it and improve that percentage in the future is time synchronization, because this is what leads to lower latency and generally improved communication. In time synchronization in a 5G network, two things are important: frequency and phase. Let’s use a visual to understand this better than words.

In the above image the two sinusoidal waves are offset by phase but have the same frequency.

In the above image, the two sinusoidal waves have the same phase but the frequency in the lower one is an integer multiple of the first one. For timing in a 5G network to be accurate, both frequency and phase must be the same in the timestamp that the master sends to the client nodes. Communication between the master and the client also happens in several steps.

With an increase in the number of devices in the network and the variations in other parameters, and for this to happen in a fraction of time, it is not very easy but possible. Time synchronization will make several applications in manufacturing possible, such as machine vision and IIoT to function aptly, making real-time monitoring of a production line possible and with robots that can receive instructions from control centers, we have an entire assembly line that is fully automated. Smart factories will become possible.

With an assembly line that is automated and where the production is as per the specifications and testing can also happen in an uninterrupted manner, there will be lesser wastage, the environment will get some much-needed reprieve, and customers will be happier too. Sustainability is one of the pillars of Industry 4.0, and of course by making advanced data analytics, IIoT, and AR possible, it enables three other major pillars of Industry 4.0 too.

What Does the Future Look Like for Manufacturing?

Manufacturing and Industry 4.0 will not be defined by 5G alone. It will use robotics for accuracy, AI to gather insights from the assembly line and data analytics and AI for predictive maintenance. It might even use augmented reality to scan with wearable glasses and allow experts to train assembly line workers remotely. The possibilities are endless and 5G will act as an enabler in several ways. If you have a 5G smartphone already, then you are already a subscriber to the 5G future of the world.

Contact Us For Business Enquiry

Rajkumar Shanmugam

Rajkumar Shanmugam is the Head of HR at ALP Consulting, bringing over 19 years of comprehensive HR leadership experience across India and international markets. His expertise spans talent acquisition, employee relations, performance management, compliance, and HR transformation. Rajkumar has a proven track record of driving people-centric initiatives, enhancing workplace culture, and aligning HR strategy with business goals. With extensive experience in US staffing operations and global mobility, he continues to lead organizational excellence through innovation and employee engagement.