8 Benefits of Using Zoho CRM for Your Business

11/07/2024

How OTT Saved the Indian Job Market?

16/07/2024Compliance in the garment industry is as golden a word as the silky threads of a traditional Kanchipuram saree for two main reasons. The first reason we use the term gold, because the idea of compliance here is very old, though it is in the last few decades that compliance in the garment industry has been given its due importance, as important as gold itself.

Second, compliance at the right time can be as precious as gold, saving a business a lot of money just in time, which could be lost in lawyer fees and compensation due to penalties charged by the government.

Introduction and Definition of Compliance in the Garment Industry

Compliance in the garment industry means adhering to the laws and regulations specified by the government and other regulatory bodies. Such compliance is difficult to follow or manage unless one has the necessary experience with managing it in a professional capacity, staying up to date on the latest conditions and clauses mentioned therein in each enactment by the government.

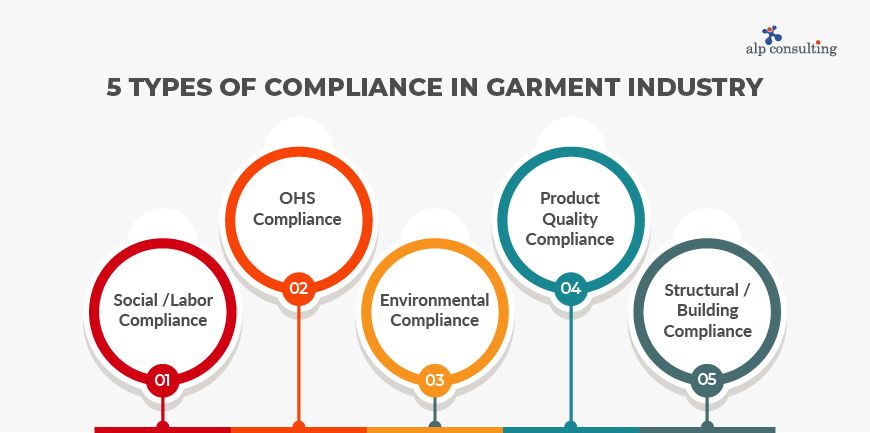

5 Types of Compliance in Garment Industry

1. Social /Labor Compliance

In social and labor compliance, you follow the compliance requirements as specified in the several labor and social protection laws. The labor laws specify a minimum working age, the disciplinary practices to be followed, the working environment, and the maximum hours to be worked among other things for each employee. Social compliance involves equality of opportunity, no bias based on caste or religion, and no discrimination based on any other human condition, that does not make the person unable to work in the necessary capacity.

2. OHS Compliance

In this type of compliance, a garment manufacturing facility must follow occupational, health and safety standards that are set by the government, the regulatory bodies, a union, or the customer or client. Such technical compliance in the garment industry includes safety of the machines that are used in the factory, prevention of fire hazards at the factory, electrical safety and awareness and prevention of damage from physical and biological hazards.

3. Environmental Compliance

The manufacturing facility has to comply with environmental regulations too, which may be a result of the laws in the current state or because of the laws prevailing in the country they are exported to. More and more European countries today are worried about sustainability, and that too, throughout the entire supply chain. For this reason, they are even demanding greater visibility into the supply chain. Some of the things you must answer are: how are you managing the waste from your factory? What impact do your activities have and how can you make them more environmentally friendly?

4. Product Quality Compliance

This is that part of technical compliance in the garment industry which affects the profits that a company makes, in the long term at least. This is about product quality. Does the product have the quality that it is advertised to have and what the customer is expecting? Is the product defective or deficient in any way? How are the materials handled during the making of the product and are there anything currently banned by the Government of India, and which the government believes could injure the customer in some way? These are some of the questions one must ask oneself in product quality compliance.

5. Structural / Building Compliance

Building assessments have now become very important after the collapse of a building that housed garment workers in Bangladesh. They look at the structural integrity of the building, its load capacity, the number of people that it can safely house and the safety of its interiors and the exteriors.

Compliance Checklist for Garment Industry

Here is a list of things we do to ensure that the garment manufacturing and packing facility is compliant with regulations:

- Look at and understand the structure of the client organization and all its entities.

- Re-evaluate what machines are used, how the facility is structured, if there any pre-existing safety devices etc.

- Check the mapping of the compliance to specific appliances and users in the company.

- Review and discuss the identified acts with the respective heads of departments.

- Identify existing gaps that need to be resolved soon and assign priority levels.

- Map existing gaps in compliance to specific users and hold them responsible for it.

- Provide training in compliance to all the users and the stakeholders involved.

- Check with the person managing compliance for the company on your behalf.

- Decide on a date by which the compliance audit process must be initiated.

Why is Compliance Important for the Garment Industry?

Compliance in the garment industry is not to be taken lightly, as it involves a lot of workers generally working in closed or tight spaces and there is a lot of machinery which could be unsafe. There may also not be proper safety and evacuation procedures in place in case of a hazard such as one rising from fire or natural causes such as a storm. These compliances ensure that the manufacturers in garment industry follow the rules and regulations that will help them prevent any untoward events.

Looking for a Compliance Partner?

Alp Consulting has over a decade of experience in managing compliance for several top companies the world over. Garment companies are increasingly making use of machines that require them to be concerned about their safety, be it those that sew clothes or those that process the raw materials further. They also need to be vigilant about wages, employee happiness and diversity and inclusion too. How can we help your garment manufacturing and packaging facility manage the compliance needs better? Talk to us today to understand how.

Contact Us For Business Enquiry

Hariharan Iyer

Hariharan Iyer is the Vice President – Operations at ALP Consulting, bringing over 40+ years of experience in HR outsourcing and labour law compliance. He leads end-to-end HRO operations, ensuring process efficiency, statutory compliance, and seamless service delivery for clients across industries. With a strong background in labour law governance and workforce management, Hariharan plays a key role in driving operational excellence and compliance-led HR solutions at ALP Consulting.